Unibeam: The Unibeam is the armor's most powerful weapon. They are also powerful enough to knock back Vibranium projectiles. In all three instances, the repulsors managed to launch the target off their feet and sent them flying back several feet. They were shown to be powerful enough to instantly cause Sam Wilson a black eye while sending him flying back several feet, to knock out Steve Rogers for nearly a minute and Bucky Barnes for several minutes. Repulsors: The Mark XLVI's Repulsors are every bit as powerful, if not more so, than its previous iterations, with nearly instantaneous charging-firing speed. The armor can fly past the Earth's Atmosphere because the armor uses energy more efficiently than its predecessors. These proved how truly durable the Mark XLVI is.Įxtreme Flight: As with all new-generation Iron Man Armors, the Mark XLVI is capable of enhanced flight via its repulsors and flight stabilizers, making it one of the most stable and fastest armors to date.

After all this, Tony only had a black eye and a few cuts on his face while the armor only had a few dents, scratches and warped paint. It is vulnerable however to precise Vibranium attacks. During the Clash of the Avengers, it proved capable of enduring mini-drones, cars, Hawkeye's powerful explosive arrows, punches and falling several hundred feet. It also has an upgraded energy shield that passively improves its durability to protect Stark. Super Strength: The armor greatly amplifies the user's base strength and combat skills to extremely massive levels.ĭurability: The armor is extremely durable, capable of withstanding blasts and extremely powerful strikes, as well as completely bulletproof. The armor also features a sentry mode, just like the Mark 43 as seen in Avengers: Age of Ultron. Just like the Mark XLIII, this armor has infrared scanners. The only other armor that has a fully retractable helmet is Ivan Vanko's Whiplash Armor Mark II Infrared Scan No other Iron Man armors have this feature. This armor also features a fully-retractable helmet. The Mark XLVI features a new micro-storage technology which allows the suit to be stored and deployed inside confined spaces like helicopters, cars, etc. It also has a partial force field protecting the armor from energy attacks. The Armor is composed of the same gold-titanium alloy, standard since the Mark III. The helmet design is similar to Mark XLV but it has a few new different indentations to the forehead. It has 28 micro-RTs placed around the body, which work as plasma channels for increased rate of fire for the repulsors. Like the Mark XLV, its armor colors have more red than gold.

It has a trapezoid-shaped indent design stationed around the circular chest RT. The polymer materials can be made in nearly any shape or size, enabling new applications for security, storm safety, military, automotive and architectural engineering.The Mark XLVI has a different and unique design to its predecessors. The company is also creating optically clear polymer transparent armor. 44 Mag handgun rounds, in a single 1.5-inch-thick sheet, weighing 8.19 lbs/sqft .”īleeding Edge is currently testing new applications for ruggedized polymers and armor composites, including a ballistic security door to protect schools from high caliber rounds and tornados. Our NIJ Level III-A transparent armor stops 9-millimeter, .357 Mag and. The panel was only 2.3 inches thick and weighed 23 pounds per square foot . “Our Humvee underbody blast panel was tested against an IED, as well as an M19 landmine, then shot with three rounds of NATO 5.56 AP with no penetration.

Urethanes are usually lighter weight and more versatile to design with than rubber and other plastics or glass used in armoring,” explains George Sturmon, founder of Bleeding Edge. “We’ve created polymers for high wear and high-impact applications such as track pads on the Abrams M1 battle tanks, landmine detonation wheels, Humvee underbody IED armor and transparent, bullet-resistant windows. George Sturmon, founder of Bleeding Edge, says urethanes are usually lighter weight and more versatile than rubber and other plastics or glass used in armoring.

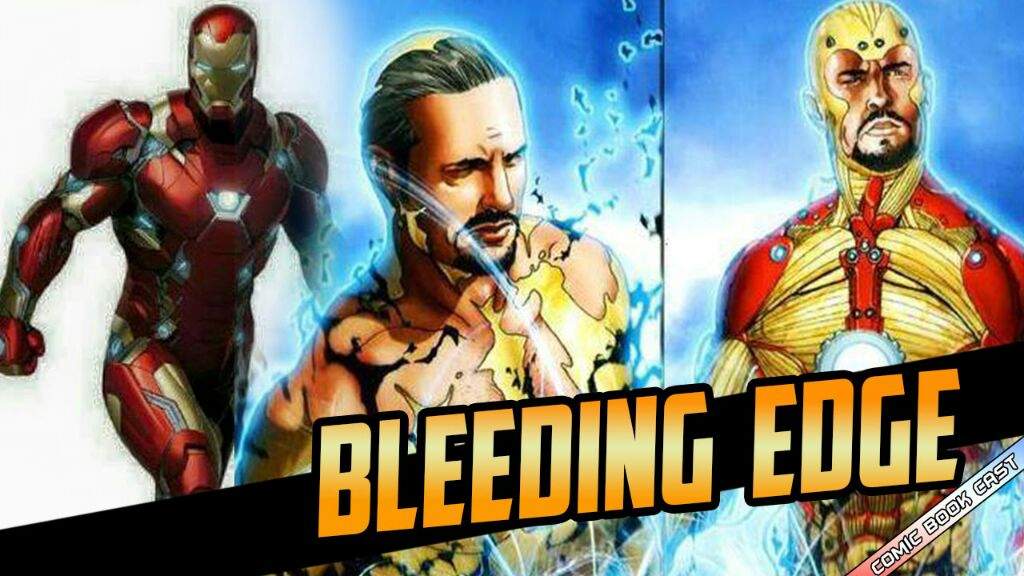

#Bleeding edge armor series#

Bleeding Edge has created a series of customized urethane composite materials that are reportedly capable of resisting the blasts from an improvised explosive device (IED) and M19 landmine, as well as a polymer transparent armor that is ballistic resistant and passes the FEMA F5 tornado impact test. Bleeding Edge Ensys (Sullivan Mo., U.S.) develops advanced impact and wear-resistant polymers for the defense and transportation industries.

0 kommentar(er)

0 kommentar(er)